1. INTRODUCTION

Shell and tube type feedwater heaters (FWHs), which are composed of hundreds of thousands of thin-wall tubes, are one of the important components in the regenerative cycle of the power generation process in nuclear power plants. As secondary coolant passes through several stages of FWHs (tube side), its temperature is raised by high temperature steam that has been extracted from the high and low pressure turbines (shell side). This heat transfer process increases system efficiency and minimizes thermal stress in the steam generator [1,2].

Butt-welded (automatic welding without the use of any filler metal) 304L austenitic stainless steel is widely used as the material for FWH tubes because of its high allowable stress, fracture toughness, and corrosion resistance. Despite those advantages, intergranular, transgranular, or mixed mode cracks have been initiated and propagate in the FWH tubes due to stress corrosion cracking (SCC), erosion or vibration [2,3]. SCC, which is considered one of the major causes of such failures, is the result of synergistic combinations of susceptible material, corrosive environment, and tensile stress.

More specifically, in pressurized water reactors (PWRs), the SCC susceptibility of austenitic stainless steels is known to be primarily influenced by water chemistry, including high dissolved oxygen (DO) and the ppm order of particular impurities (Cl and S) [3-7]. For example, Xie et. al [8] has reported the effect of Cl on the SCC susceptibility of stainless steel. Despite its superior SCC resistance in PWR conditions, the addition of 30 ppm Cl increased its SCC susceptibility. It was also observed that the presence of 2 ppm Cl could result in SCC failure regardless of S content [9]. Ruther et. al [10,11] suggested a specific water chemistry of DO (0.2 ppm) and S (0.1 ppm) to prevent the SCC of stainless steels. Water chemistry affects the formation and destruction of oxide film along cracks and at their tips by changing electrochemical parameters, such as the Cr/Fe ratio in the oxide film, etc. In addition, material aspects like sensitization, cold work (or heavy deformation) and associated residual stress can also increase SCC susceptibility [8-19].

In recent years, the authors have observed SCC failures of high pressure FWH tubes (200−240 °C of inlet/outlet temperature) under PWR operation even after short-term operation, after re-tubing or replacement. Cracks were detected by nondestructive examination and finally confirmed by microstructure analysis. The cracks initiated at the outer surface of the base metal (opposite the welded region) and propagated through the thickness in a transgranular cracking mode. Considering that impurities (less than 10 ppb Cl and S) and hydrogenated water chemistry (less than 5 ppb DO) of the secondary coolant were controlled, the mechanism of this sudden failure is more likely to be associated with material aspects rather than water chemistry.

Therefore, in this study, the differences in the microstructural features (grain, dislocation, and phase), micro-hardness and circumferential residual stress of failed and non-failed SCC FWH tubes were assessed and compared to identify the factors affecting failure events during PWR operation. Finally, the results are discussed in relation to technical specifications to improve the material requirement of FWH tubes for nuclear power plant application.

2. MATERIALS AND METHODS

2.1 Materials

In this study, three 304L austenitic stainless steel tubes (samples A, B, and C with 16 mm outer diameter and 1.27 mm thickness) from different manufacturers were selected. Among these tubes, sample A was known to have superior SCC resistance from plant experience while samples B and C underwent large numbers of SCC failures. It is worth mentioning that the test samples were spare material taken from tubes that had not been exposed to PWR operating conditions.

The chemical compositions of the tubes were analyzed using the inductively coupled plasma (ICP) method with CS Determinator (ELTRA SC-2000) and the results were compared to ASTM A688/A688M-15, which is the technical specification of the FWH tube, as listed in Table 1. It can be seen that the chemical composition of each tube is quite similar and satisfies the specification. Parts of the tubes were additionally heat treated in high purity helium at 1080 °C for 0.5 h. In this case the holding time was much longer than that used in real tube fabrication. The purpose of the additional heat treatment was to compare the residual stress remaining on the tubes before and after heat treatment.

In this study, the effect of sensitization, which is one of the major material factors affecting SCC, was not considered, since all as-received samples exhibited a non-sensitized condition after testing in accordance with ASTM A262 practice A (not shown in this paper).

2.2 Microstructural analysis

For the microstructural analysis by optical microscopy (OM, Leica DMi 8A) and electron back scattered diffraction (EBSD) equipped with focused ion beam (FIB, Helios G4 UX), the tubes were cut into pieces 5 mm in length and mounted with conductive resin. The mounted samples were ground and automatically polished down using a 1 μm diamond suspension and then finished by colloidal silica suspension for 20 min. For the OM analysis, electrolytic etching was conducted using a solution of methanol and perchloric acid (9:1 ratio) at 1 V for 1 min to reveal grain boundaries. In this way, the grain distribution of the asreceived and heat-treated tubes was analyzed along the radial direction (outer, middle, and inner area). The average grain size was measured using an image analyzer (TOMORO analySIS TS).

In addition, the microstructure features including grain orientation, twin formation, and phases in the outer, middle, and inner areas of the tubes were further assessed by EBSD at 15 kV. In the analysis, the input data for face-centered cubic (FCC) structured Fe (with a lattice parameter of 0.358 nm) and body-centered cubic (BCC) structured Fe (lattice parameter of 0.286 nm) were used with a scanning step size of 2 μm. The OM and EBSD analysis of the tubes were conducted at areas opposite (180°) the weld region, since this was the location where cracks were found following plant operation. To observe the dislocations formed in the asreceived tubes, samples 3 mm in diameter and 0.2 mm in thickness were fabricated, ground, and jet-polished. Transmission electron microscope (TEM, Talos F200X) analysis was conducted at 200 kV in a STEM mode.

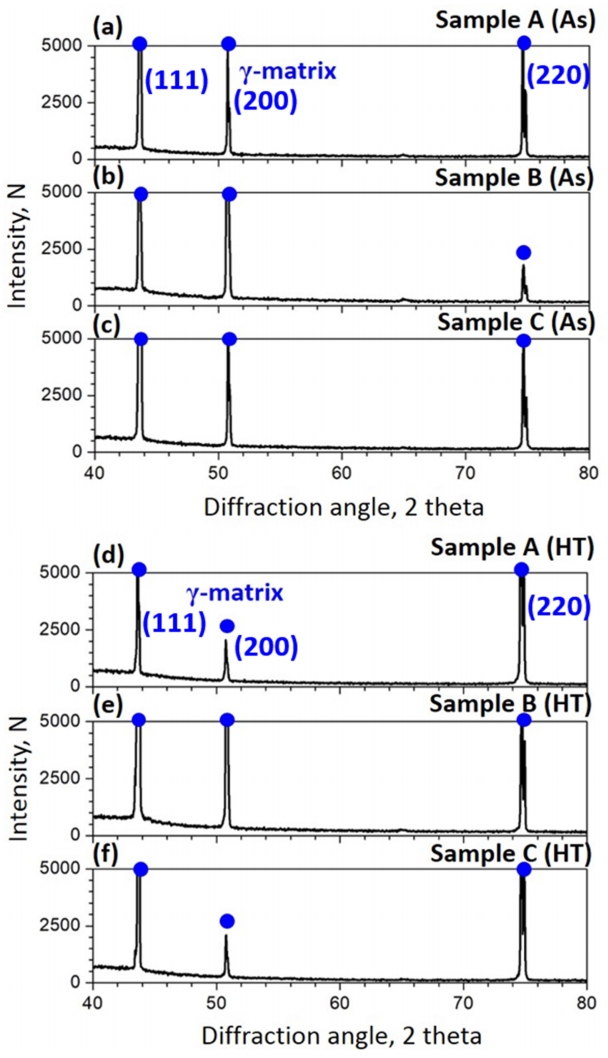

To confirm the phases that were present in the tubes, an X-ray diffractometer (XRD, RIGAKU D/MAX-2500) was used. As the area in the radial direction was not large enough to conduct X-ray diffraction, the tubes were cut in a longitudinal direction and mounted/polished to make a flat region. For the XRD analysis, the theta/two theta mode was used with a high applied power of incident X-ray beam (40 kV and 300 mA) and a diffraction angle of 40° to 80°.

2.3 Micro-hardness and residual stress measurement

The micro-hardness values of the as-received and heat-treated tubes were measured to assess hardness distribution along the radial direction. The test was conducted at areas opposite the weld region in accordance with the microstructure observation. For the measurement, the thickness was divided into five equal sections 0.2 mm from each outer and inner surface. Vickers micro-hardness tests were conducted with a load of 0.3 kg and the hardness values were obtained by averaging at least five measurements in each section.

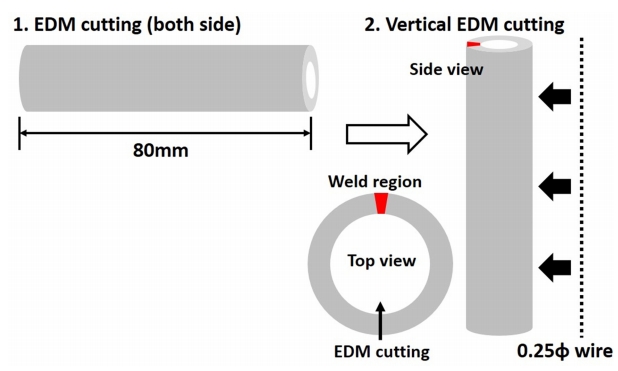

For the circumferential residual stress measurement of the as-received and heat-treated tubes, a split-ring method was used. It was usually applied to the thin-tube, where the thickness is less than one tenth of the outer diameter. It was assumed that the presence of linear distribution of stress field existed while not locally. Electro discharge machining (EDM) was used in the sample preparation because residual stress can be easily affected by external factors introduced by a cutting process.

Figure 1 shows the schematics of the test procedures used in this study. The ends of the tubes were cut into 80 mm lengths by EDM. Then, the section opposite the weld region was also cut by EDM with a wire 0.25 mm in diameter at a speed of 0.1 mm/min. Finally, the splitting distance of at least 20 points was measured in each sample by OM and converted to residual stress (σθ, MPa) as the following from (1) to (4) [20,21].

where Mr is (Residual moment), E (modulus of elasticity), a (inner radius of tube), b (outer radius of tube), r (radius of ring thickness), and δ (change in width after splitting).

3. RESULTS AND DISCUSSION

3.1 Comparative microstructure evaluation of FWH tubes

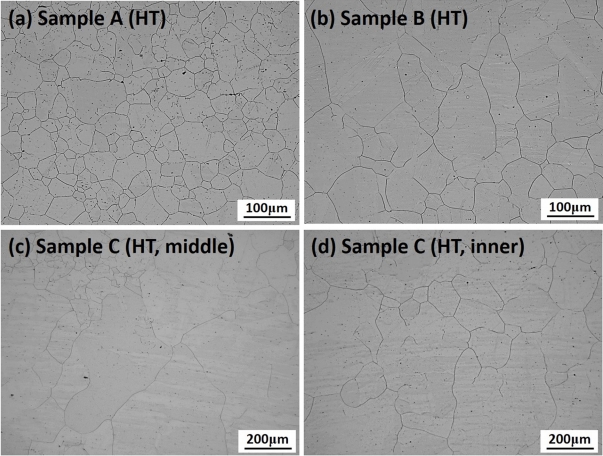

Figure 2 and 3 are OM micrographs of the FWH tubes showing the microstructures of the as-received and heat-treated samples. The results of grain size measurements, average grain size and ASTM grain number are also summarized in Table 2. As shown in the figure, the grains are uniformly distributed with an average grain size of ~30 μm in the as-received sample A (Fig 2a) and are ~60 μm in the as-received sample B (Fig 2b). Meanwhile, the grain distribution of as-received sample C was nonhomogeneous along the radial direction. The grain sizes of the outer and middle areas were ~20−30 μm (Fig 2c) but the inner area had much larger grains (over 100 μm, Fig 2d).

Despite these differences among the tubes, they were all acceptable as FWH tube material since there is no restriction in the specification. After heat treatment at 1080 °C for 0.5 h, the grain sizes of all the tubes increased, as shown in Fig 3. For the heat-treated samples A and B, the grain sizes were measured to be ~40 μm (Fig 3a) and ~70 μm (Fig 3b), respectively. For heat-treated sample C, the grain sizes were greater than 200 μm (Fig 3c and d) indicating abnormal grain growth as compared to samples B and C. Although the specific annealing conditions, such as temperature, holding time, and cooling rate, etc. vary for each manufacturer, the phase stability at high temperature (degree of grain increase) of sample C was the lowest among the tubes when the same heat treatment was applied.

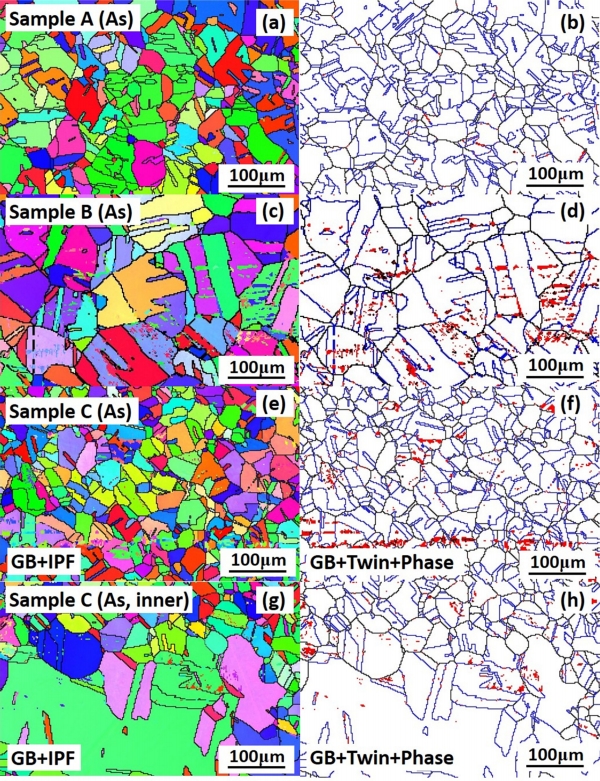

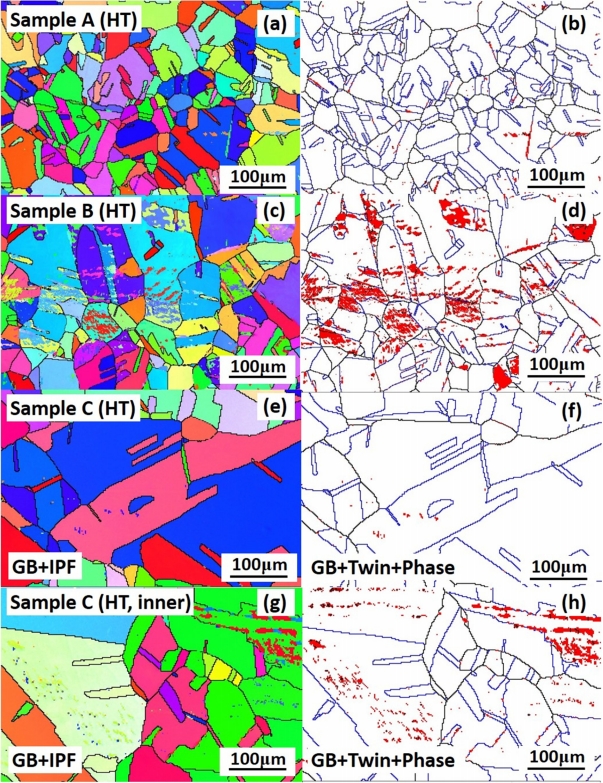

Figure 4 and 5 show the EBSD results of the as-received and heat-treated FWH tubes. In the as-received tubes (Fig 4), the grains were randomly distributed (left figures) with a large amount of twin boundaries (blue color in the right-hand figures) throughout the γ-matrix. In accordance with the OM analysis, the inner region of sample C exhibited much larger grains. Moreover, the BCC phase (red color in the right-hand figures) was present, especially in samples B and C, as stringer-type within the grains, twins, or grain boundaries. Even after additional heat treatment was carried out, the twin boundaries and BCC phase still existed, as shown in Fig 5.

Regarding the presence of the BCC phase with a lattice parameter of 0.286 nm, there are two possible ways that it can be formed in austenitic stainless steels [22]. First, α’-martensite could be formed by solid-state phase transformation during heavy plastic deformation, cold working, or surface grinding, which is often called deformation induced martensite (DIM) or strain induced martensite (SIM) [23-25]. 304 stainless steel in particular is more likely to contain α’-martensite compared to 316 stainless steel because of its relatively low stacking fault energy. Meanwhile, the α’-martensite is transformed to γ-matrix when it is exposed to temperatures of 750 °C and above, even for a very short exposure period (few min) [26,27]. Thus, the BCC phase observed in this study cannot be identified as α’-martensite, since the phase did not disappear after longer exposure to higher temperature.

On the other hand, δ-ferrite is often present in not only weld materials but also base metal as a stringer type. For those reasons, the BCC phase observed in the EBSD analysis could be identified as a δ-ferrite formed by the solidification process of the base material, but not by tube fabrication and/or straightening processes. In order to clarify the overall content of the BCC phase observed in EBSD, XRD analysis was carried out. Fig 6 shows the results of the XRD analysis of the tubes indicating the γ-matrix was observed in all test conditions. Therefore, it can be said that a very small amount of the BCC phase was locally distributed in the as-received and heat-treated samples B and C, while it was rarely present in sample A.

It is known that α’-martensite induces an intense local strain field in the surrounding area since the phase change is generally accompanied by volume expansion. Also considering its hard and brittle nature, this could easily lead to SCC initiation and propagation [15,16]. On the other hand, the effect of δ-ferrite on SCC susceptibility remains controversial. For instance, austenitic stainless steel weld and duplex stainless steels are known to have high SCC resistance due to the high Cr content of δ-ferrite, which can form a protective oxide film [17]. Meanwhile, when it is continuously present, cracks can propagate easily at the δ-ferrite/γ-matrix interface. Rao et al. [18] also observed that higher δ-ferrite content resulted in increased SCC susceptibility. At this stage, the effect of the very small and partial presence of δ-ferrite in samples B and C on SCC has not been clearly determined, although it might seem to be negligible.

3.2 Assessment of circumferential residual stress by split-ring test

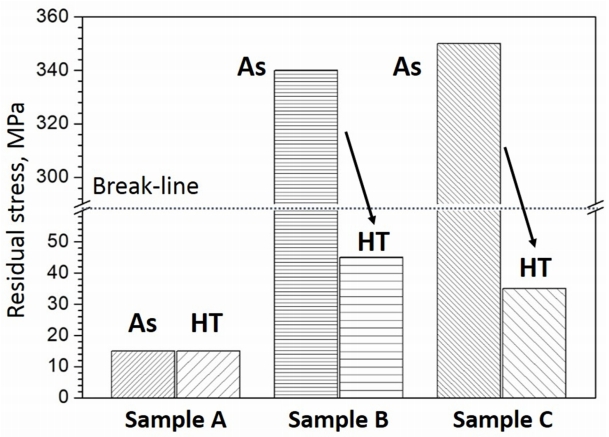

After the split-ring tests, the splitting distance of the outer surface of the as-received and heat-treated tubes were compared, as shown in Table 3. The splitting distances of the as-received and heat-treated sample As were almost the same, ~310 μm. Meanwhile, for the as-received samples B and C, they were around ~610 μm and ~600 μm, which decreased to ~340 μm and ~330 μm after heat treatment, respectively. Considering that the 250 μm diameter cutting wire generally removes ~300 μm from the adjacent region, the changes in splitting distance caused by residual stress in samples A, B, and C were ~10 μm, ~310 μm, ~300 μm for the as-received condition and ~10 μm, ~40 μm, ~30 μm for the heat-treated condition, respectively. By applying the quantitative method described in Section 2.3, the splitting distance of the tubes with respect to residual stress value in MPa was calculated, as shown in Fig 7 and Table 3. For sample A, the circumferential residual stress in both the asreceived and heat-treated conditions was very low, 15 MPa. On the other hand, the as-received samples B and C showed tensile circumferential residual stresses of about 340 and 350 MPa, which were at least 20 times larger than that of sample A. However, these decreased to 45 and 35 MPa after heat treatment, indicating the relaxation of residual stress. Meanwhile, the X-ray method was also used to validate the ring-split test (not shown in this paper) which indicated that the residual stress of all the heat-treated tubes decreased to almost zero, similar to the results of the ring-split test.

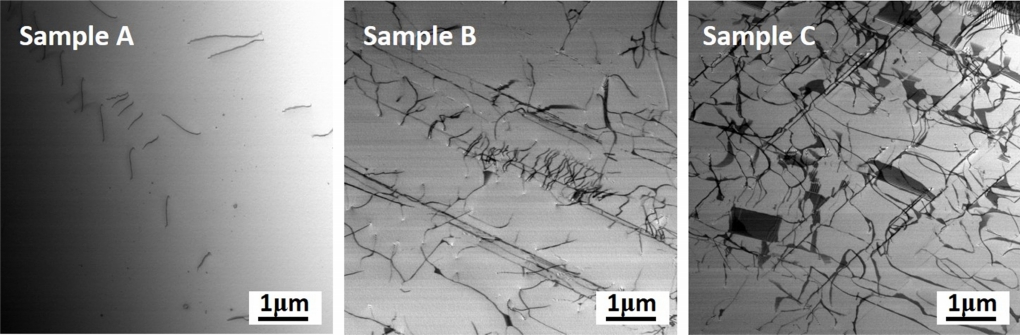

Figure 8 shows the transmission electron microscope (TEM) micrographs of the as-received FWH tubes. Samples B and C exhibit larger amount of dislocations than sample A in accordance with residual stress. During FWH tube fabrication, straightening is conducted by either stretching or rolling after solution annealing. In the rolling process (samples B and C), stress is directly applied to the outer surface of the tubes, resulting in severe work hardening compared to the stretching process (sample A).

It has previously been reported that there is a strong correlation between residual stress and SCC susceptibility [12-16,19]. Lu et al. [19] reported that compressive residual stress and grain refinement effectively decreased SCC susceptibility compared to a specimen with tensile residual stress applied. It was reported that larger residual stress resulted in higher crack initiation rate and crack density [12]. In addition, Ghosh et al. [14] found that SCC crack propagation was dependent on the direction of the residual stress resulting from the straightening process. Stretching and rolling straightening caused longitudinal and circumferential residual stress, respectively, resulting in transgranular crack propagation perpendicular to the direction of residual stress. Those studies indicate that not only the presence of tensile residual stress increases SCC susceptibility but also its effect on the degree and direction of the cracking phenomena.

3.3 Micro-hardness distribution along the thickness direction

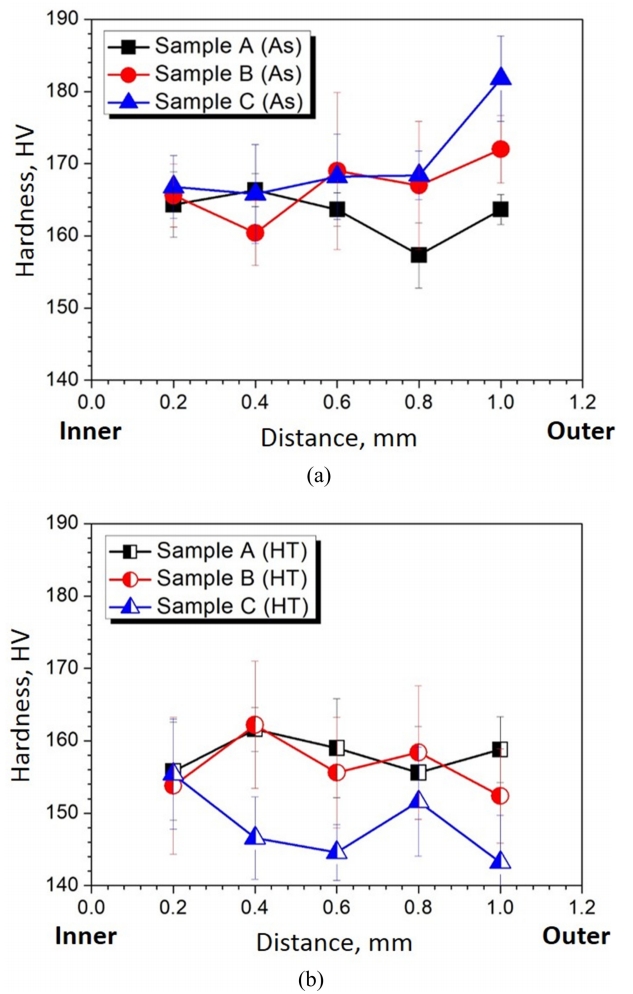

Figure 9 shows the results of the Vickers micro-hardness measurements (average and standard deviation) of the asreceived and heat-treated tubes. In the as-received condition (Fig 9a), the hardness values of sample A are uniformly distributed along the radial direction while those of samples B and C have an increasing trend from the inner to the outer area. In addition, the hardness values of the inner and middle areas of all tubes are similar, but diverge at the outermost area, with the values being larger in the order of sample C, B and A. The hardness value of sample C at the outermost area is almost close to 190 HV, which is the limit of the material requirement of 90 HRB. Meanwhile, when heat treatment was carried out (Fig 9b), the hardness values of all tubes decreased and the increasing tendency in samples B and C disappeared.

In general, the hardness value can be influenced by grain size, residual stress, precipitates, etc. Among these factors, the increasing tendency in micro-hardness in the as-received samples B and C could be explained by presence of a large residual stress along the radial direction, since such tendency disappeared after additional heat treatment.

Meanwhile, for heat-treated sample C, the significant decrease in hardness value could be affected not only by the reduction in residual stress, but also by the abnormal grain growth. Although all values still satisfied the maximum hardness values in the material requirement, the presence of large residual stress could be related to SCC susceptibility.

In this regard, water chemistry should be maintained below the operating guideline to ensure the long-term integrity of stainless steel tubes from SCC failure. Moreover, this study indicates that straightening by stretching is beneficial in terms of low residual stress, as compared to use of a rolling process. Meanwhile, when the rolling process is used, additional heat treatment could be a practical method to reduce the residual stress in FWH tubes.

4. CONCLUSIONS

In this study, three 304L austenitic stainless steel FWH tubes from different manufacturers were investigated. By comparing microstructural features, micro-hardness, and residual stress of tubes that failed (samples B and C) and did not fail (sample A) by SCC under actual PWR operation, the following conclusions were drawn:

1) For the tubes which experienced a large number of SCC failures, significant tensile circumferential residual stresses were observed in addition to a large amount of dislocation, and an increasing tendency in micro-hardness values toward the outer regions. The presence of large residual stress is thought to increase SCC susceptibility.

2) Such residual stress could be generated by work hardening that occurred during straightening by rolling process, since that method directly applies stress to the surface of the material. In contrast, the stretching process resulted in low residual stress. Meanwhile, when additional heat treatment was carried out, the hardness values were significantly reduced.

3) This indicates that straightening by stretching process is beneficial to increasing the SCC resistance of FWH tubes in terms of low residual stress. On the other hand, when the rolling process is used, additional heat treatment could be a practical method to reduce residual stress in FWH tubes.